Description

This product is discontinued and is replaced by the DCU 408E Engine Controller.

The DCU 408 is an engine supervision unit without a local user interface. This is for use where there is no requirement for local control or indication of the systems such as in a cramped or unattended engine room.

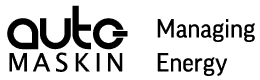

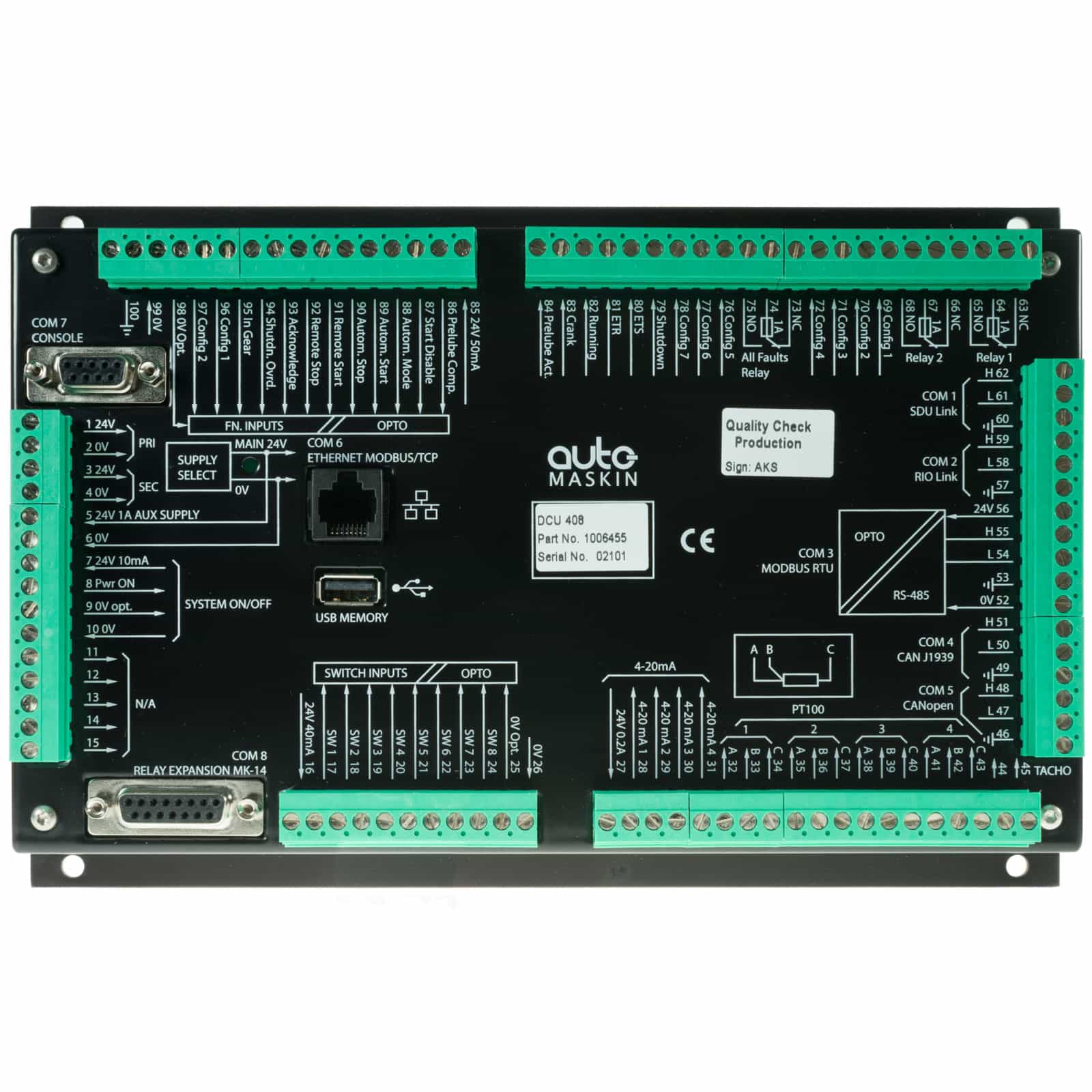

This unit (or the DCU 410 ) is a basic requirement to build a supervision system for both variable speed (propulsion or pumps) or fixed speed (generating set) diesel engines . It is a compact unit suitable for off engine mounting in a steel enclosure. The DCU 408 accept inputs from J1939 CAN bus links, CANopen interfaces, Modbus RS485 and up to 16 analogue or digital inputs in its own right. It provides outputs in all these digital formats and via a standard Ethernet connection.

The DCU 408 also provides engine control logic and the outputs required, including but not limited to, Pre-Lubrication control, start & stop signals, both ETR and ETS, plus remote interfaces for these functions. Connections are made via clearly labelled connectors on the front of the panel needing no specialist tools.

The unit provides an interface via Ethernet to connect an RP 410 remote panel for remote indication, or via an AV interface module to any customer supplied screen.

Why more customers select the DCU 408

Customers of the DCU 408 find that the simple, self configuring connections and functionality are prime reason to select this model across many applications and uses on board ship that require compliance to global standards. With some applications not requiring local control and indication, the DCU 408 provides a significant cost reduction compared to other solutions.

With 10 languages including Chinese and Russian built in, the information the product can display remotely is easy to understand, leading to better operational decisions. The ability of the unit to connect to other ships systems without sophisticated software or specialist tools makes it installable and usable by non experts.

Customizable by a simple laptop with a web browser and a standard Ethernet cable, the password protected areas allow more flexible configuring or customization when required. With a literally “plug & play” capability, The DCU 408 configures all other elements of the Marine Pro system automatically.

Holds internally up to 40 customer selectable configuration files via a “startup wizard”

Connectable to multiple engine types and or ships systems

Suitable for fixed and variable speed applications

Pre printed connection function on units

Simple connectivity – no special tools

Pre loaded configurations to meet Classification Society rules for UMS

Ethernet connectivity means plug and play within global standards

Simple two wire communication via Modbus to Marine Pro I/O expansion modules

Affordable expandability to create a small ships alarm system

Scoped to suit applications

Simple mounting in enclosure

Use existing monitors to display data