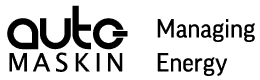

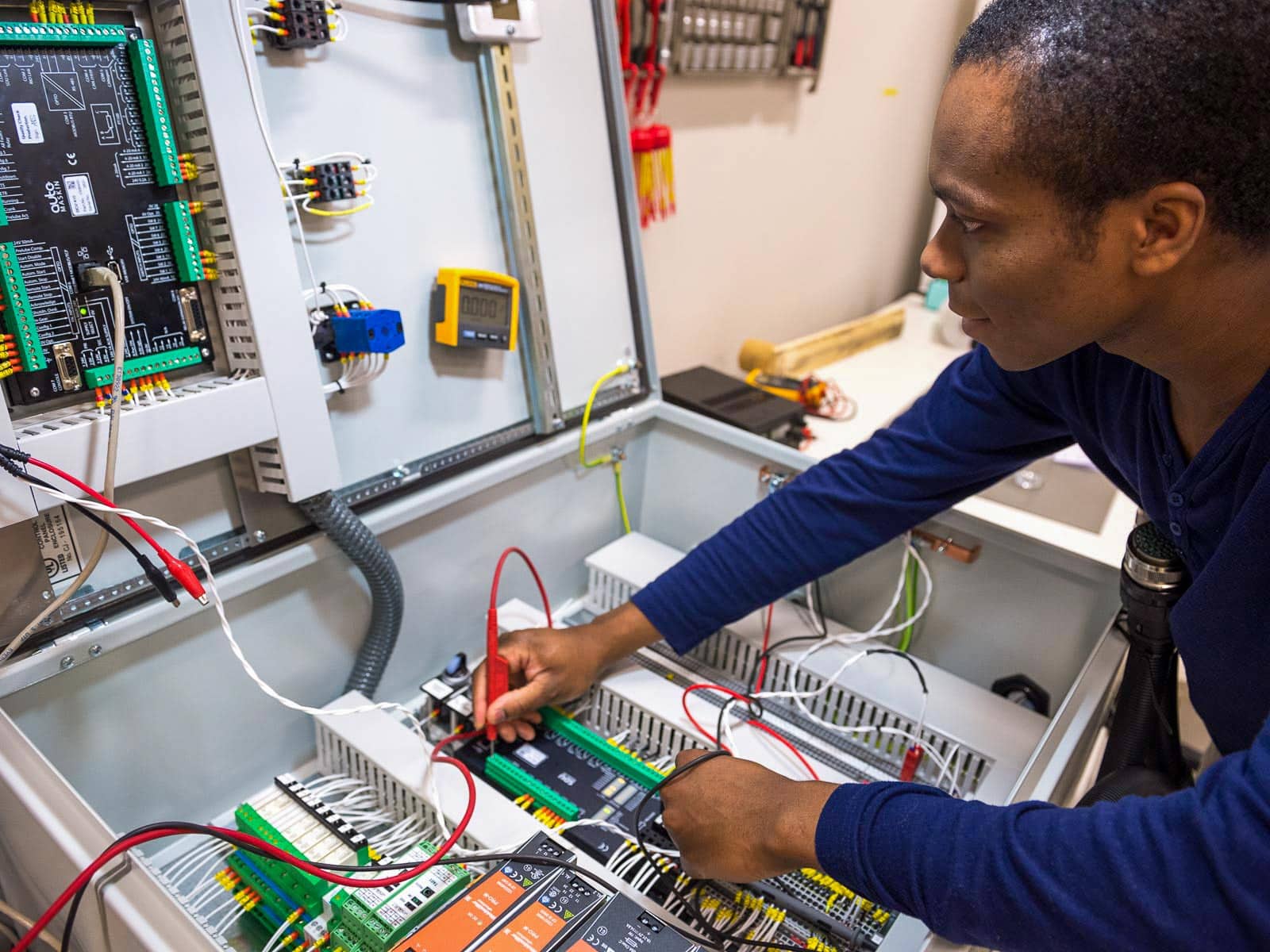

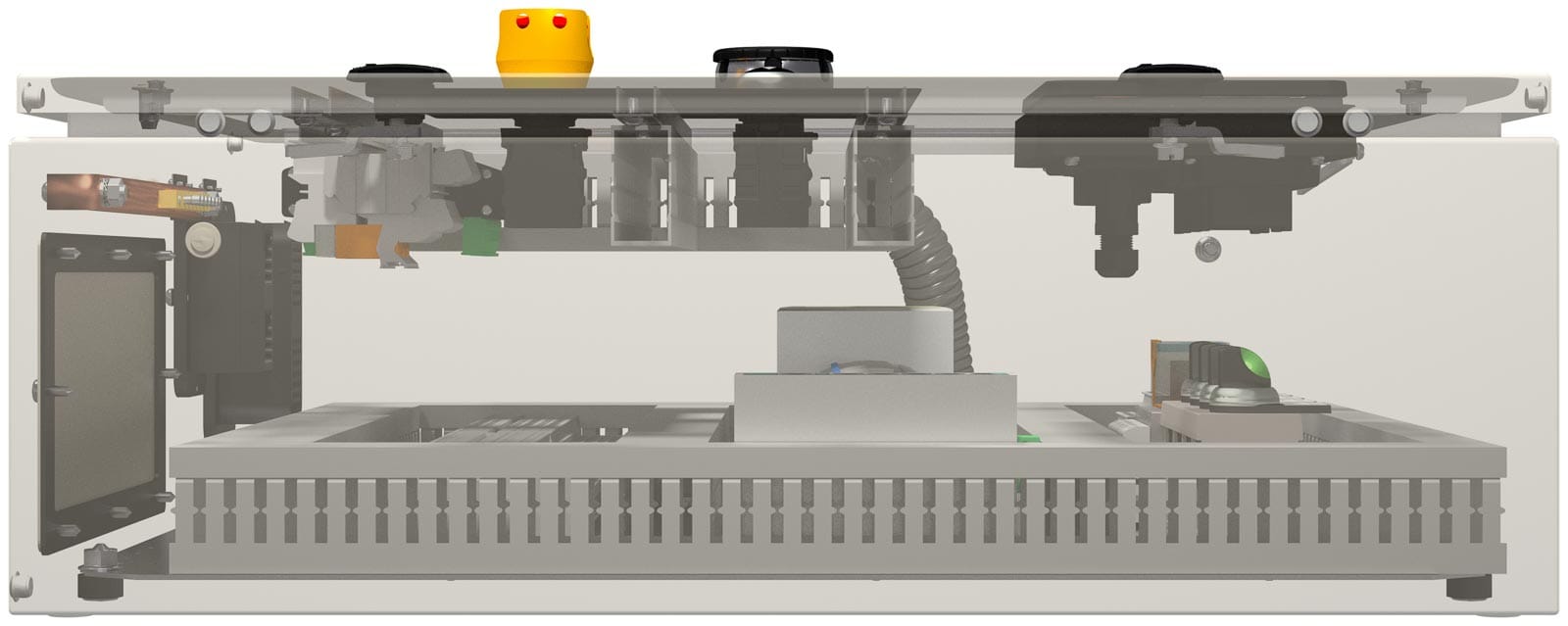

Did you know that Auto-Maskin is a high-volume provider of control cabinets to the marine industry? This year, Auto-Maskin will manufacture close to 2000 control cabinets for several marine applications. The control cabinets range from space-effective systems for small diesel gen-sets to bigger cabinets that include automation for a number of vessel systems.

The annual volume of 2000 cabinets is a good number but nowhere near the limit of production capacity. Marita Lundberg, Logistics and production manager, explains why. “We have several production lines in Europe, all with spare capacity and set up to manage even more resources on the floor than with the current level of production”. Marita continues – “this flexibility makes us desirable for bigger OEM’s out there that has to obey to market fluctuations and deliver on demand, often with volume ramp-up on short notice”.

Despite the diversity in volumes, cabinet size and functionality, there is one common factor: quality. Auto-Maskin has incorporated ISO and APQP standards across the production that make customers completely trust us to ship directly from end-of-line testing to the end customer, it is a huge cost saving for many of our customers. Top that with full integration to customers EDI systems.

But what is the selling point? The answer is One stop shop. In addition to the production, Auto-Maskin possesses all disciplines in-house to manage a complete engineering project from a-z. We safely navigate through all sides of a cabinet project together with our customer, supported by modern CAD tools and professional project management. Resources are pulled from the Auto-Maskin development centre and the engineering department, to solve whatever challenges the customer throw at us.

The combination of performing the engineering and design together with production enable us to capture several challenges before they reach the end-user and becomes a cost.

Do you have a future panel project at hand – try us!